Trial Products Reports

At Bi-Metal, we do

trials on most our products, to see if we really want to introduce these new

items to our clientele. When we do this we get to know the positives and

negatives of these products. The testers usually focus right away on the cost

of the product, even though they don’t pay for them. On great products the

costs are usually recovered at the half way point or closer the end of the

products lifetime. People that usually complain about costs of new products are

not looking at the complete picture. Here are some thoughts that need to be

considered when trying something new.

- Is it safe? (health wise and injury wise)

- Does it have CSA approval? (if required)

- Is product environmentally friendly? (Can it be recycled?)

- Does it improve labor productivity over present product? (time)

- Does the product do the job it was designed for being done just as easy

as or better than existing product?

- What about damage to product while being used?

We just lately have done or

in the middle of some trials on 3 different diamond grinding discs and the new

BI-4002 series turning inserts.

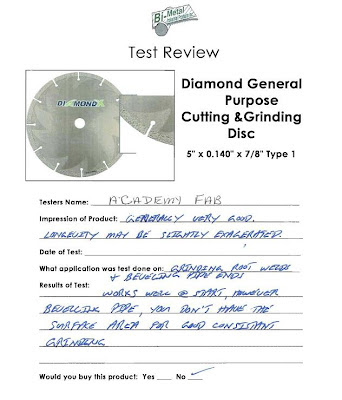

The first diamond disc was described to be used for

grinding and cutting off. It was a

flat 5” x .140 disc (see review below) and is double sided. We sent it to a

piping shop which does a lot of pipe welding work. Here is the tester’s feedback.

We thank Ken and Rusty at Academy Fabrication for

their input. They did have

some other comments when we picked up the test sheets like “This disc would do

really well to cut steel grading and may do a lot better in a steel fabrication

place.” Over all down side the surface area on side of disc is only

approximately 5/8” deep and for pipe beveling it should be at least 1-1/2”

deep.

The second diamond disc was described to be used for

grinding hard surfacing. It was a

flat 5” x 1/4 disc (see review below) and is double sided. We sent it to a hard

surfacing shop which does a lot of specialized oil down hole tooling work. Here

is the tester’s feedback.

We thank Trevor and Brad at Plasma-Tec for their

input. They did have some other

comments when we picked up the test sheets like “This disc is way better than

your competitors but see if you can get the hub attachment redesigned. This is

much better than using conventional abrasive stones.” Over all down a good

product except hub.

If you have any interest in any of our tested products

give us a call or email.

No comments:

Post a Comment